A concrete highway is built of slabs, a complex structure composed of various layers and components. Understanding the intricacies of concrete highway construction provides valuable insights into their durability, sustainability, and maintenance requirements. This article delves into the components, construction methods, advantages, disadvantages, environmental impact, maintenance techniques, and future trends of concrete highways, offering a comprehensive overview of these vital transportation networks.

Components of a Concrete Highway

Concrete highways consist of multiple layers, each with a specific function:

- Subgrade:The foundation layer, typically composed of compacted soil or crushed rock, provides support and drainage.

- Base:A layer of compacted granular material, such as crushed stone or gravel, distributes loads and prevents cracking.

- Surface:The topmost layer, made of concrete, provides the driving surface and resists wear and tear.

Concrete used in highway construction includes:

- Portland Cement Concrete (PCC):A common type of concrete, composed of cement, water, aggregates (sand and gravel), and admixtures.

- Asphalt Concrete (AC):A mixture of asphalt cement, aggregates, and fillers, providing flexibility and durability.

- Roller-Compacted Concrete (RCC):A low-cement concrete compacted with rollers, used in base layers and pavements.

Construction Methods for Concrete Highways

Concrete highway construction involves several steps:

- Subgrade Preparation:Grading and compacting the subgrade to provide a stable foundation.

- Base Placement:Laying and compacting the base material to create a uniform and supportive layer.

- Concrete Placement:Pouring the concrete mixture onto the prepared base and leveling it using screeds.

- Finishing:Smoothing and texturing the concrete surface using finishing machines or hand tools.

- Curing:Protecting the concrete from moisture loss and temperature changes to ensure proper hydration and strength development.

Specialized equipment used includes concrete mixers, pavers, screeds, and finishing machines.

Advantages and Disadvantages of Concrete Highways: A Concrete Highway Is Built Of Slabs

Advantages:, A concrete highway is built of slabs

- Durability:Concrete highways can withstand heavy traffic and extreme weather conditions.

- Strength:Concrete provides high compressive and flexural strength, reducing the risk of cracking.

- Low Maintenance Costs:Concrete highways require less frequent maintenance and repairs compared to other surfaces.

- Long Lifespan:Concrete highways can last for decades with proper maintenance.

Disadvantages:

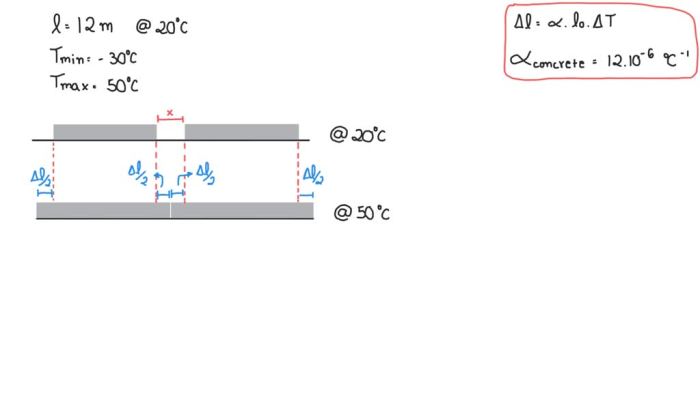

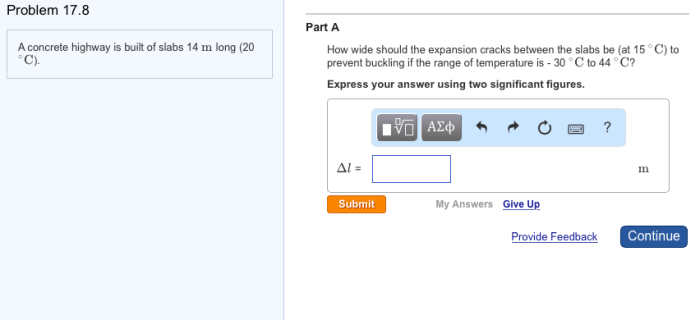

- Susceptibility to Cracking:Concrete is susceptible to cracking due to temperature changes, traffic loads, and subgrade settlement.

- Higher Initial Construction Costs:Concrete highways are generally more expensive to construct than asphalt highways.

- Noise:Concrete highways can generate more noise than asphalt highways due to their hard surface.

Compared to asphalt highways, concrete highways offer better durability, strength, and longevity, but have higher initial construction costs and may be more susceptible to cracking.

Key Questions Answered

What are the main components of a concrete highway?

A concrete highway typically consists of a subgrade, base layer, and surface layer, each with specific materials and functions.

How are concrete highways constructed?

Concrete highway construction involves preparing the subgrade, laying the concrete, and finishing the surface using specialized equipment and techniques.

What are the advantages of concrete highways?

Concrete highways offer durability, strength, low maintenance costs, and improved safety compared to other pavement types.

What are the disadvantages of concrete highways?

Concrete highways can be susceptible to cracking, have higher initial construction costs, and require specialized maintenance techniques.

How can the environmental impact of concrete highways be minimized?

Sustainable practices, such as using recycled materials and implementing energy-efficient construction methods, can reduce the environmental impact of concrete highways.