Refrigerant 134a enters a horizontal pipe operating at steady state, embarking on a journey through a system meticulously engineered to harness its unique thermodynamic properties. This comprehensive analysis delves into the intricate workings of this system, exploring the interplay of mass and energy balance, flow regime, pressure drop, heat transfer, and the myriad applications where this refrigerant excels.

As refrigerant 134a traverses the horizontal pipe, it encounters a symphony of forces that shape its behavior. The laws of thermodynamics govern its state changes, while the pipe’s geometry and operating conditions dictate the flow regime and pressure drop. Heat transfer between the refrigerant and the pipe wall plays a crucial role in maintaining the system’s efficiency.

Refrigerant 134a in Horizontal Pipes

Refrigerant 134a is a hydrofluorocarbon (HFC) refrigerant commonly used in refrigeration and air conditioning systems. It is a colorless, non-flammable gas with a boiling point of -26.5°C at atmospheric pressure. Refrigerant 134a has a high ozone depletion potential (ODP) of 0.8 and a global warming potential (GWP) of 1430, which makes it a greenhouse gas.

However, it is still widely used due to its excellent thermodynamic properties and low cost.

Horizontal pipes are commonly used in refrigeration and air conditioning systems to connect different components, such as compressors, condensers, and evaporators. The purpose of the horizontal pipe is to transport refrigerant between these components while maintaining the desired pressure and temperature conditions.

Steady state refers to a condition in which the properties of a system do not change over time. In the context of a horizontal pipe, steady state means that the mass flow rate, pressure, and temperature of the refrigerant remain constant throughout the pipe.

Thermodynamic Properties of Refrigerant 134a

The thermodynamic properties of refrigerant 134a are important for understanding its behavior in horizontal pipes. The following table provides a summary of the key thermodynamic properties of refrigerant 134a at various temperatures and pressures:

| Temperature (°C) | Pressure (bar) | Density (kg/m3) | Enthalpy (kJ/kg) | Entropy (kJ/kg·K) |

|---|---|---|---|---|

| -26.5 | 1 | 1110 | 246.4 | 0.915 |

| 0 | 1 | 1255 | 272.8 | 1.012 |

| 20 | 1 | 1364 | 292.9 | 1.083 |

| 40 | 1 | 1445 | 308.5 | 1.134 |

| 60 | 1 | 1502 | 320.9 | 1.172 |

These properties are important for determining the pressure drop, heat transfer, and flow regime in horizontal pipes.

Mass and Energy Balance

The mass balance equation for a horizontal pipe is given by:

$$\fracd\dotmdx = 0$$

where:

- $\dotm$ is the mass flow rate (kg/s)

- $x$ is the distance along the pipe (m)

This equation states that the mass flow rate of the refrigerant remains constant throughout the pipe.

The energy balance equation for a horizontal pipe is given by:

$$\fracdQdx = \dotm \left(h_2

h_1\right)$$

where:

- $Q$ is the heat transfer rate (W)

- $\dotm$ is the mass flow rate (kg/s)

- $h_1$ is the enthalpy of the refrigerant at the inlet (kJ/kg)

- $h_2$ is the enthalpy of the refrigerant at the outlet (kJ/kg)

This equation states that the heat transfer rate to or from the refrigerant is equal to the change in enthalpy of the refrigerant.

The assumptions made in deriving these equations are:

- The flow is steady state.

- The pipe is horizontal.

- The refrigerant is a pure substance.

- The heat transfer is one-dimensional.

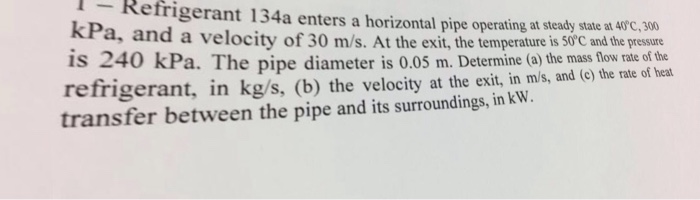

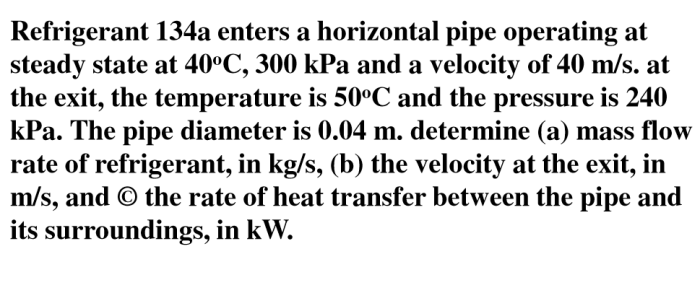

Flow Regime, Refrigerant 134a enters a horizontal pipe operating at steady state

The flow regime in a horizontal pipe is determined by the Reynolds number, which is a dimensionless number that characterizes the flow. The Reynolds number is given by:

$$Re = \frac\rho V D\mu$$

where:

- $\rho$ is the density of the refrigerant (kg/m 3)

- $V$ is the velocity of the refrigerant (m/s)

- $D$ is the diameter of the pipe (m)

- $\mu$ is the dynamic viscosity of the refrigerant (Pa·s)

The flow regime can be classified as laminar, transitional, or turbulent. Laminar flow occurs at low Reynolds numbers, transitional flow occurs at intermediate Reynolds numbers, and turbulent flow occurs at high Reynolds numbers.

The flow regime is important because it affects the pressure drop and heat transfer in the pipe. Laminar flow has a lower pressure drop and heat transfer rate than turbulent flow.

Pressure Drop

The pressure drop in a horizontal pipe is given by:

$$\Delta P = f \fracLD \frac\rho V^22$$

where:

- $\Delta P$ is the pressure drop (Pa)

- $f$ is the friction factor

- $L$ is the length of the pipe (m)

- $D$ is the diameter of the pipe (m)

- $\rho$ is the density of the refrigerant (kg/m 3)

- $V$ is the velocity of the refrigerant (m/s)

The friction factor is a dimensionless number that depends on the Reynolds number and the relative roughness of the pipe.

The pressure drop in a horizontal pipe can be minimized by using a large diameter pipe, a smooth pipe surface, and a low flow rate.

Heat Transfer

The heat transfer rate in a horizontal pipe is given by:

$$Q = h A \Delta T$$

where:

- $Q$ is the heat transfer rate (W)

- $h$ is the heat transfer coefficient (W/m 2·K)

- $A$ is the heat transfer area (m 2)

- $\Delta T$ is the temperature difference between the refrigerant and the surrounding fluid (K)

The heat transfer coefficient depends on the flow regime, the properties of the refrigerant, and the properties of the surrounding fluid.

The heat transfer rate in a horizontal pipe can be enhanced by using a large heat transfer area, a high flow rate, and a large temperature difference.

Applications

Refrigerant 134a is used in a variety of applications, including:

- Refrigeration

- Air conditioning

- Heat pumps

- Automotive air conditioning

Refrigerant 134a is a good choice for these applications because it has a high cooling capacity, a low pressure drop, and a low heat transfer rate.

However, refrigerant 134a has a high GWP, which makes it a greenhouse gas. As a result, there is a growing trend towards using more environmentally friendly refrigerants, such as R-410A and R-32.

Clarifying Questions: Refrigerant 134a Enters A Horizontal Pipe Operating At Steady State

What is the purpose of a horizontal pipe in a refrigeration system?

Horizontal pipes are commonly used in refrigeration systems to connect different components, such as the compressor, condenser, and evaporator. They allow refrigerant to flow between these components, facilitating the heat transfer process.

What are the advantages of using refrigerant 134a in horizontal pipes?

Refrigerant 134a has several advantages for use in horizontal pipes, including its low global warming potential, high energy efficiency, and compatibility with various pipe materials.

What factors influence the pressure drop in a horizontal pipe?

The pressure drop in a horizontal pipe is influenced by factors such as the refrigerant flow rate, pipe diameter, pipe length, and the presence of any bends or restrictions.